CHEMICAL

The chemical industry plays a crucial role in many sectors, including the production of basic chemicals, petrochemicals, pharmaceuticals, plastics, polymers, paints and coatings, foods and fertilizers. The chemical process lines often involve complex sequences of chemical reactions, physical processes and material processing to convert raw materials into final products.

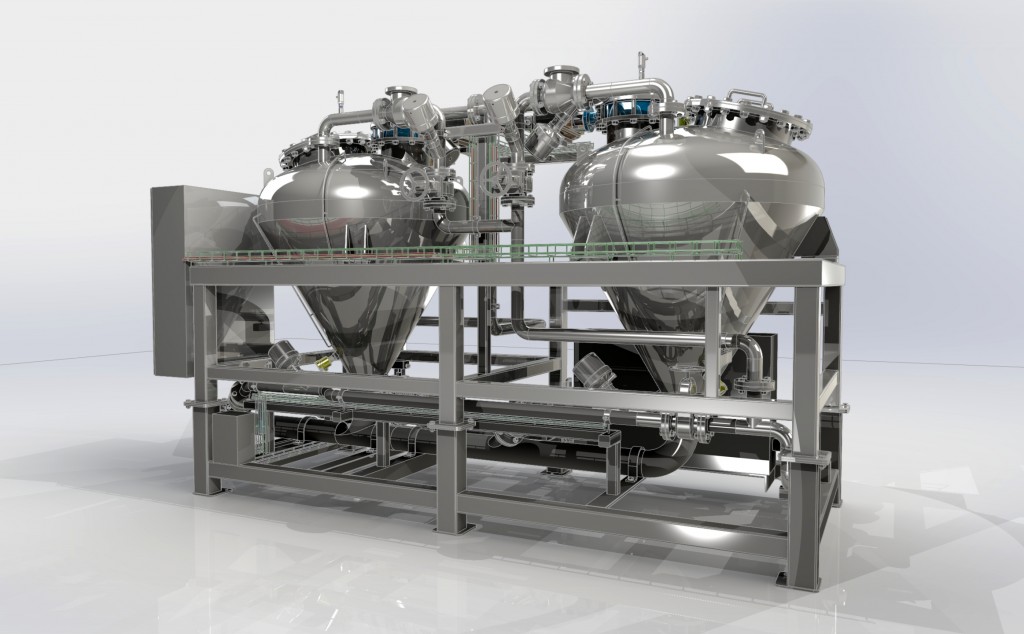

ST-Projects specializes in building turnkey solutions in the chemical industry. This includes greenfields, but also the optimization or adjustment of existing processes.

In addition to turnkey solutions, we can also serve you as a component supplier. Our specialists are aware of the latest developments, legislation and guidelines in your industry.

Our many years of experience in the chemical industry make us your preferred partner in:

regulations

Safety is key in the chemical process industry due to the inherent risks of working with chemicals and hazardous processes. We are aware of strict safety standards and regulations to ensure the health and safety of employees, the environment and the communities in which they operate. But also consider the regulations regarding air pollution, water pollution and soil pollution.

Production processes

The chemical process industry involves complex and varied production processes. We can advise you in the processes of distillation, reaction, extrusion, polymerization, fractionation, crystallization, filtration and other units to convert raw materials into semi-finished or finished products.

quality control

Samples are taken and checked for quality and safety during the entire process. Samples are taken from different parts of your process, according to the drawn up sampling plan. This is done by using manual or automated sampling equipment.

Atex

Especially in the chemical industry, situations can arise in which explosive atmospheres are created, mainly due to the presence of dust, gases or vapors from certain production processes. It is therefore extremely important to take the correct safety measures to prevent explosion hazards. We identify your hazardous areas, carry out a risk inventory and classification, implement preventive measures and draw up a plan for maintenance and inspection of equipment and installations in order to identify and prevent potential defects or problems in a timely manner .

how can we service you?

We would like to get in touch with you to discuss your plans and issues without any obligation. Together we can take your process to a higher level!